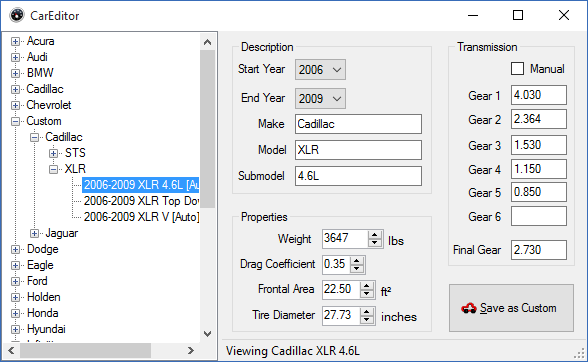

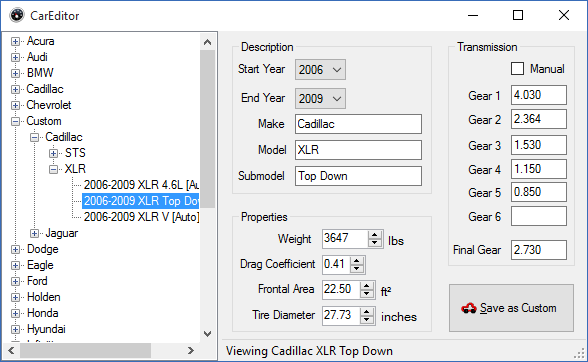

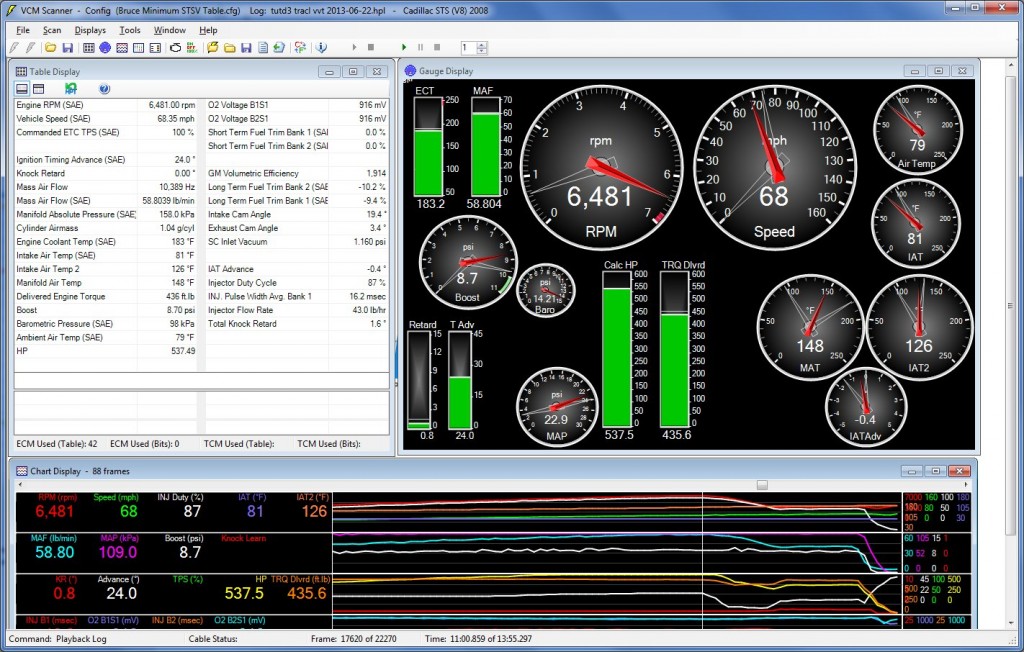

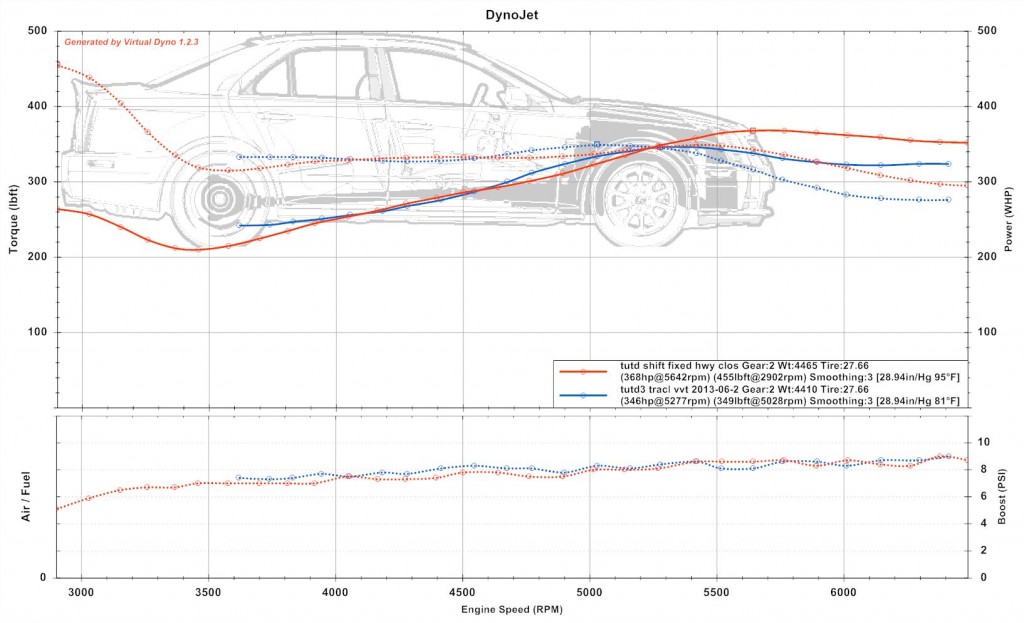

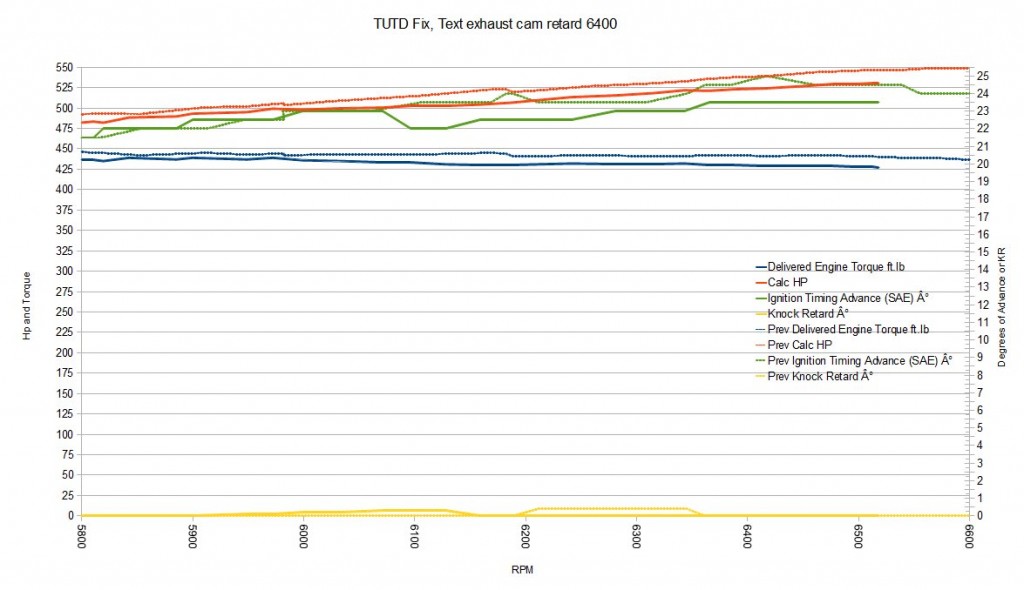

Using my initial and second (premium) run data captured from HPTuners, I did some Virtual Dyno Analysis (see my initial Virtual Dyno article here). First I needed a new custom file for the XLR:

I had run the test data with the top down (worse aerodynamics), and I used a back-to-back wind tunnel test of a different car (Miata) to model the degradation of top down as .06 CD. I will want to run virtual dyno tests with top up in the future?

I created a 2nd custom file to model the XLR with top down:

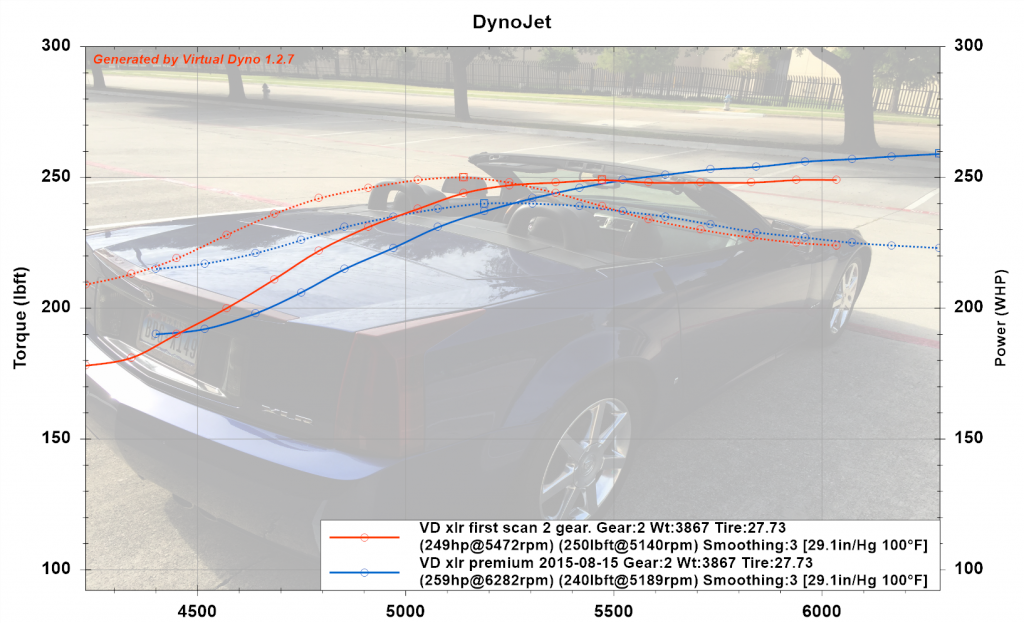

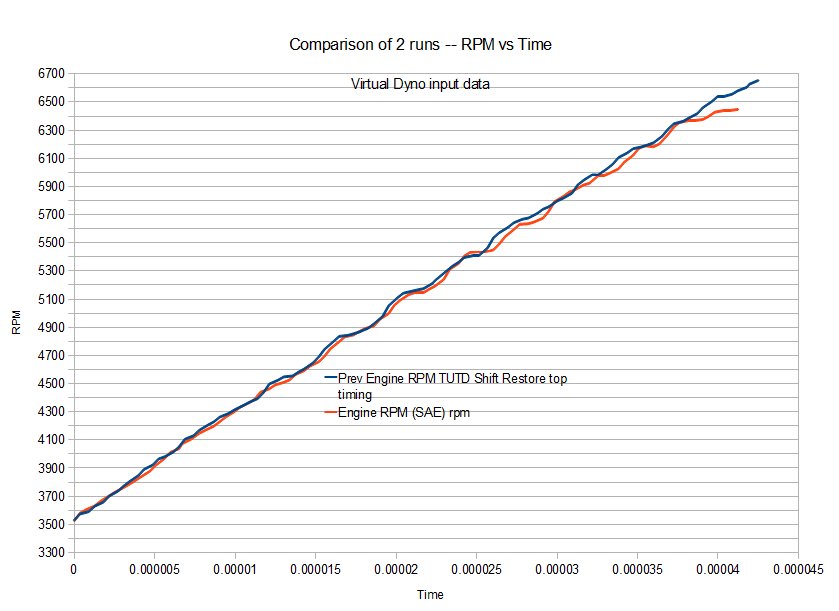

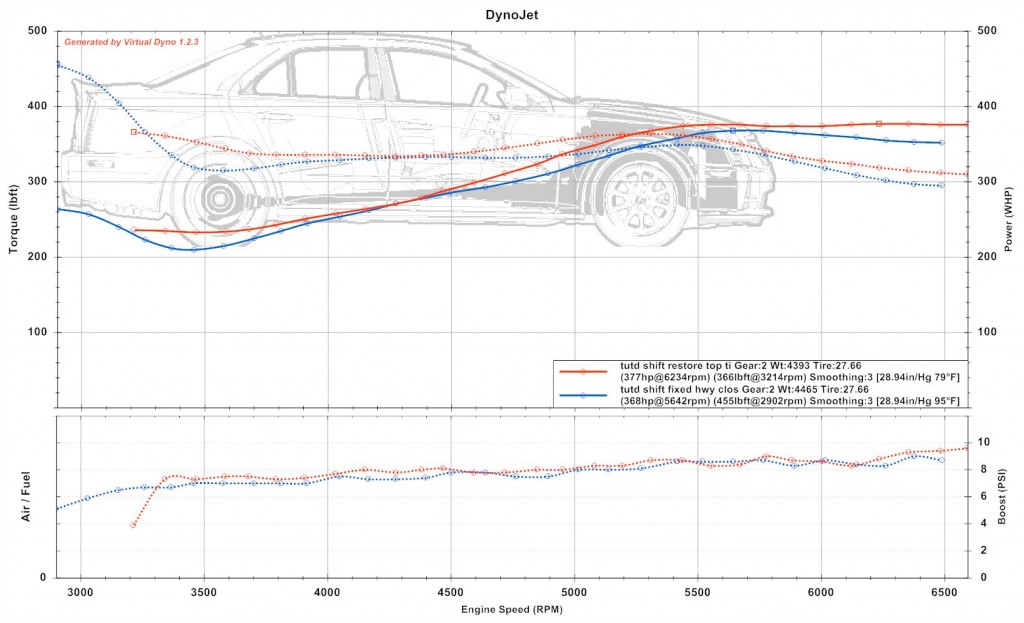

I edited the .csv saves from Hptuners to only include the acceleration range desired, and loaded both runs.

[click on image to zoom in, back to return]

I adjusted the SAE conditions for the pressure and temps during the test, 29.1 in/hg baro and 100F. The car intake air was actually a bit higher. I am not sure this adjustment is quite right — the reference site suggests a dyno adjustment of 4.5% for test conditions. The Virtual Dyno not-SAE – to SAE goes from 251 to 259 or a 3.2% increase. A 4.5% increase would be 262 whp, so not much difference really.

The results, 249 whp for the initial test, and 259 whp for the known-quality premium fuel test, seem consistent with expectations. 259 whp / 0.8 transmission losses = 324 hp. Cadillac rated the stock XLR LH2 V8 engine at 320 hp.

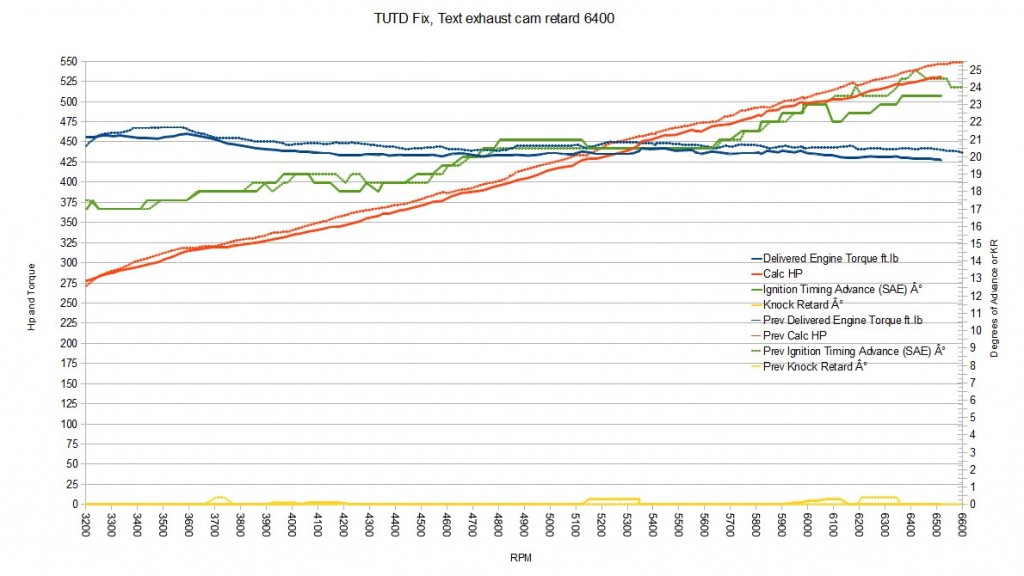

One might conclude the difference between believed-regular unleaded and known premium unleaded in this test case was 10 whp (13 hp). This is similar (9 hp) to what the calculated hp values showed.

The calculated engine hp vs virtual dyno:

Initial: 2nd gear 293 calc hp x 1.045 conditions adj = 306 hp

Virtual Dyno 249 whp / .8 trans loss = 311 hp

Premium: 2nd gear 302.3 calc hp x 1.045 conditions adj = 315 hp;

Virtual Dyno 259 whp / .8 trans loss = 324 hp

Or told in the other order:

Initial: 306 adj hp x .8 trans loss = 244 whp

Virtual Dyno: 249 whp

Premium: 315 adj hp x .8 trans loss = 252 whp

Virtual Dyno: 259 whp

Note in both tests 1st gear calculated hp was higher, and for comparison with Virtual Dyno analysis of the same runs I am using 2nd gear hp data.

Virtual Dyno depends on consistent, level test area, weights (with/without fuel for example), and conditions for comparable results. It has however been tested over and over to be consistent with dynojet results when done with proper care.

My conclusion is that I need to do a few more captures of consistent test data for Virtual Dyno use, but the configuration files I have predict results consistent with my other indicators.