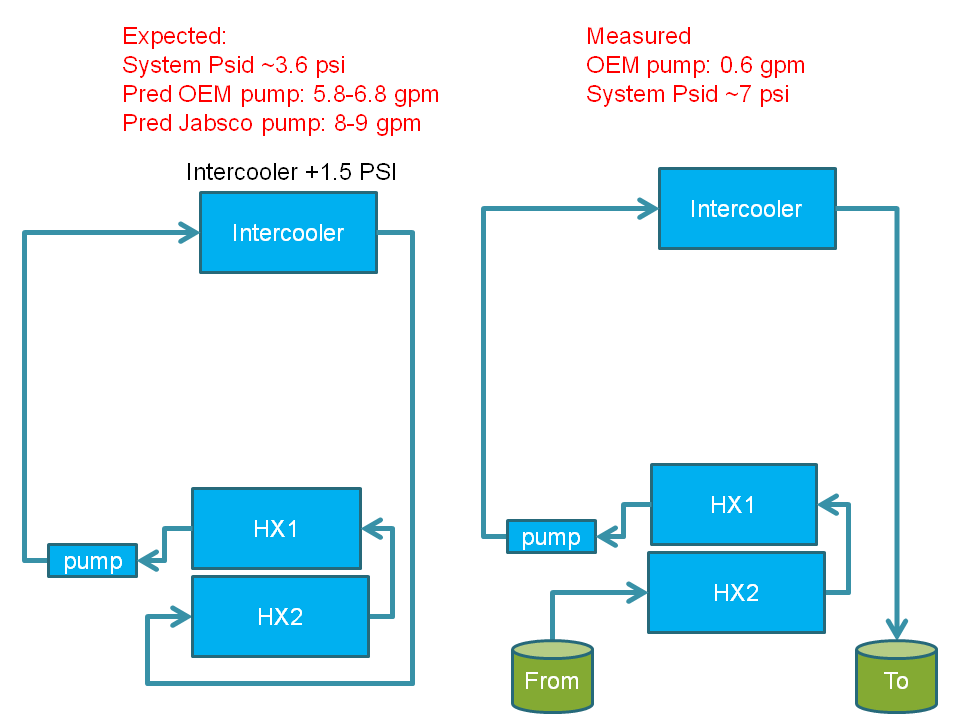

UPDATE: Re-ran the test with a change in the test setup, yielding closer to the expected results. See Below.

I hate surprising test results.

I was expecting to see around 3-4 PSID system head, and the Bosch OEM intercooler pump doing 5-6 gpm.

This morning I ran a bucket test on my Cadillac STS-V. A bucket test is a simple way to measure gallons per minute of flow in an operating system. To do the test, measure how much fluid comes out of the system over what period of time. Record the result in gallons per minute.

First I calibrated my bucket. I used a “TO” bucket that was shaped like a cylinder, with no slope to the sides. That simplifies measurement. I took a large 1/2 gal kitchen measuring cup and put 1/2 gallon of water in “TO” my bucket. Then I measured how many inches of depth were in the bucket. My bucket measured 1&1/4″ per 1/2 gallon. I added another 1/2 gallon and noted that the bucket was at 2.5″; good.

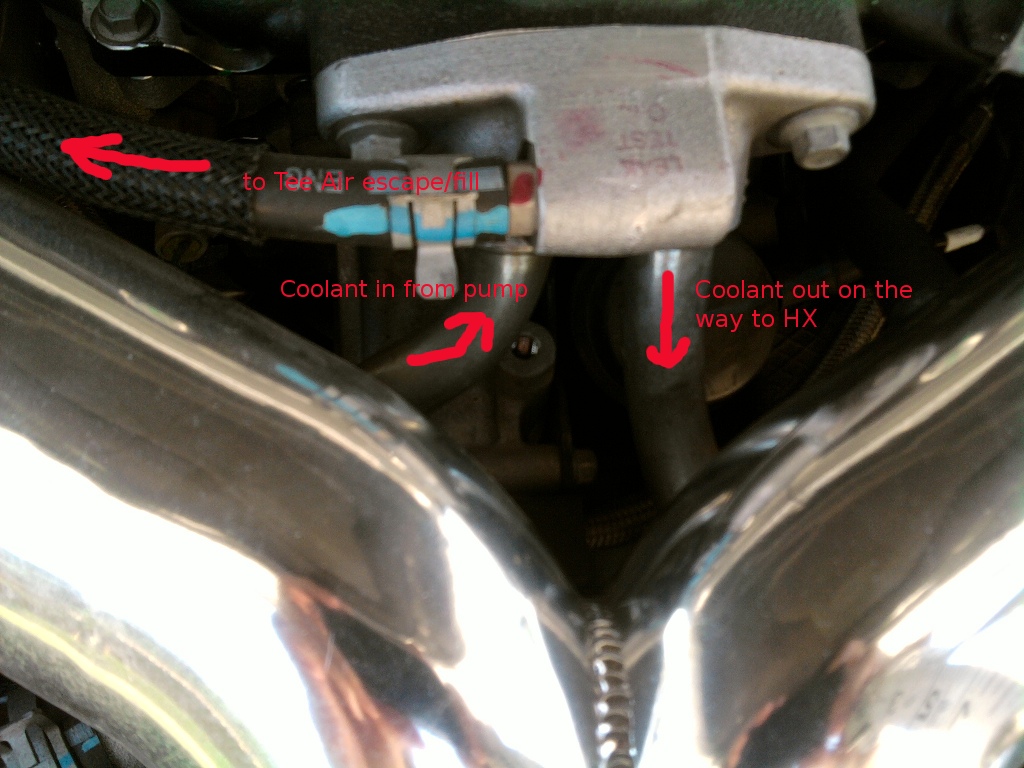

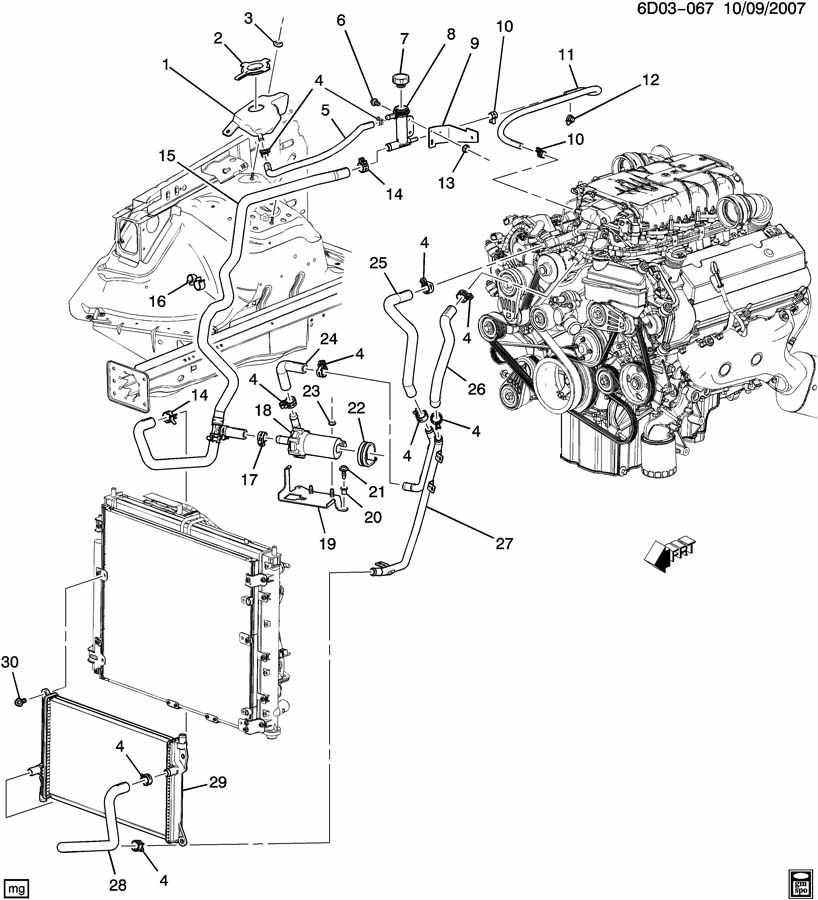

Next, I put the STS-V up on jackstands, and removed the undertray. I disconnected the hose from the hard pipe out at the bottom of the V coming out of the intercooler, and put a “out” hose there leading to my “TO” bucket. I put the hose that had been connected there in my “FROM” bucket. I added coolant to my “From” bucket, and ran the test.

The pump in the test is the Bosch OEM intercooler pump. It is pumping through the intercooler, and pulling from both heat exchangers so that the flow should exactly model what the pump sees in operation.

What I measured was a meager 1 & 1/2″ of flow per 60 seconds. Since 5/4″ was 1/2 gallon, 6/4″ is 20% more or 0.6 gallons per minute (GPM). That means that the current pressure head in the system as tested is nearly 7 PSID. The Bosch pump can only pump against a max of 7.3 psi.

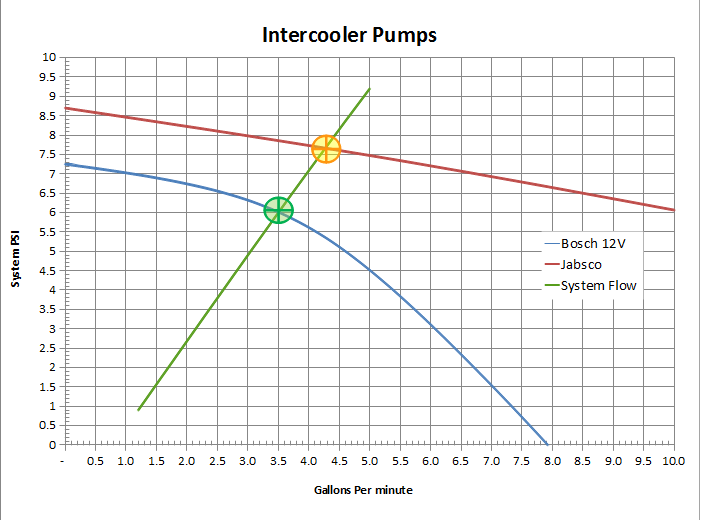

I plan to test with a Jabsco pump next. The Jabsco pump is rated up to 8 PSID, and at 7 PSID might be able to push 4 or 5 gpm.

What would you change in the test setup? Hit the comments!

Did my test setup effect the outcome? If the “FROM” bucket was elevated to the same level as the intercooler at the top of the engine, would that be more fair? Or does the down force from the intercooler height to the bucket get ‘counted’ in the flow out the “TO” hose already and so is not ‘lost’?

Next:

- Re-run the bucket test

- Check all hoses for crimping

- Raise the “FROM” bucket to intercooler level

- Test with the engine on, not just battery/pump on with engine off as before — full voltage

Update — Raise the Bucket:

Re-ran the test with the from bucket at intercooler height. New pump flow 3.5 gpm, much closer to expected. 40″ of water height is a static 1.4 psi into the system that is there in operation but missing from my initial result.

For this test I put the “FROM” bucket at 42″ height, or the intercooler height in the car. I did that because the hoses and pipes leading to where I put the “FROM” bucket are the downhill flow from the intercooler. I pushed water through the FROM line to prime the line and ensure that I got gravity siphon flow through the line and into the car. With the bucket and line in place the system actually flowed 1.2 gpm with NO pump running. So the height of the bucket makes a difference — each foot of height of water gives 0.42 psi, so 3.3 feet equates to 1.4 psi or so. My original test had the FROM bucket on the ground, so inadvertently took away this 1.4 psi of system pressure.

I ran the engine at idle when I was testing the pump. With the pump on in the retest the system did a steady 3.5 gpm flow.

This suggests that at 3.5 gpm the system pressure head is around 6 psi assuming the OEM bosch intercooler pump is operating to spec.

It also ties with the first test result given the setup difference.

The test perhaps also points to the system psid curve versus flow — 1.4 psi at 1.2 gpm flow, and 6 psi at 3.5 gpm flow. We expect psid to go up as a function of nearly the square of the change in flow, so this also seems appropriate.

Now, my system resistance of 6 psid may still be higher than it should be; I am looking at the fittings to see if they can be improved further.

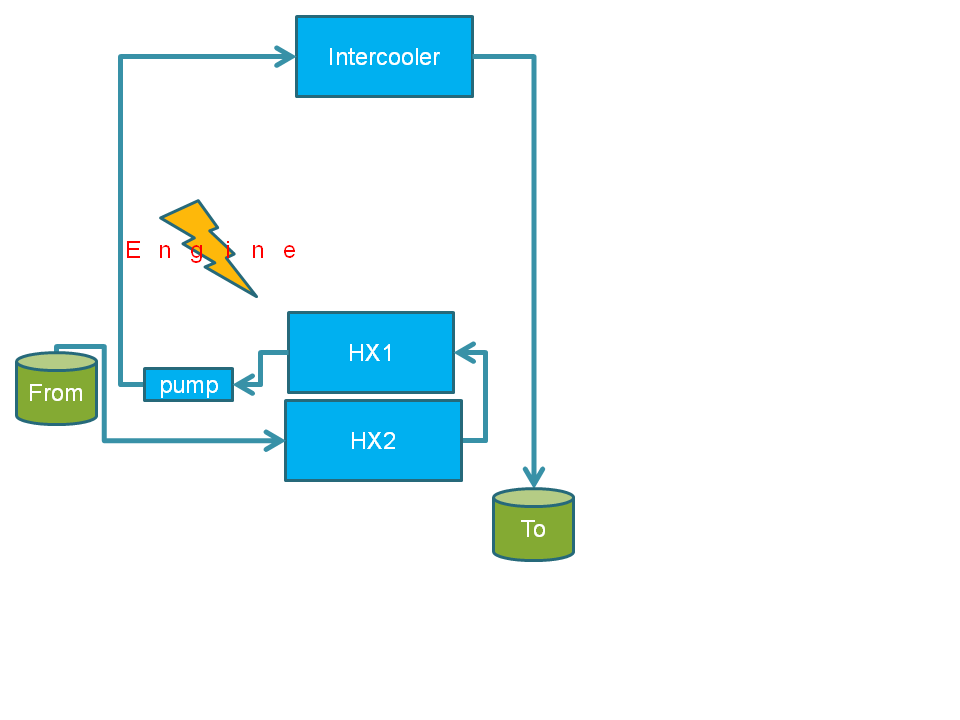

If the system numbers are correct than the system flow resistance would be shown by the green line on the chart above. The Y axis shows pressure head. The X axis is in gallons per minute of flow. The blue line is the Bosch OEM pump spec. The red line is the Jabsco pump spec. Where the system flow line crosses the pump lines are where we would expect that pump to operate in gpm and PSID in this system. So in other words, if the Bosch pump is doing 3.5 gpm against 6 psid, and the system characteristic curve is correct, then the Jabsco pump will do 4.3 gpm which will raise the system pressure head to 7.7 psid.