Water injection or methanol injection is a system that injects water or a mix of water and methanol into the intake of the engine. The fluid spray vaporizes, absorbing heat. This removes heat from the cylinder, acting as a sort of chemical inter-cooling for supercharged or turbocharged engines.

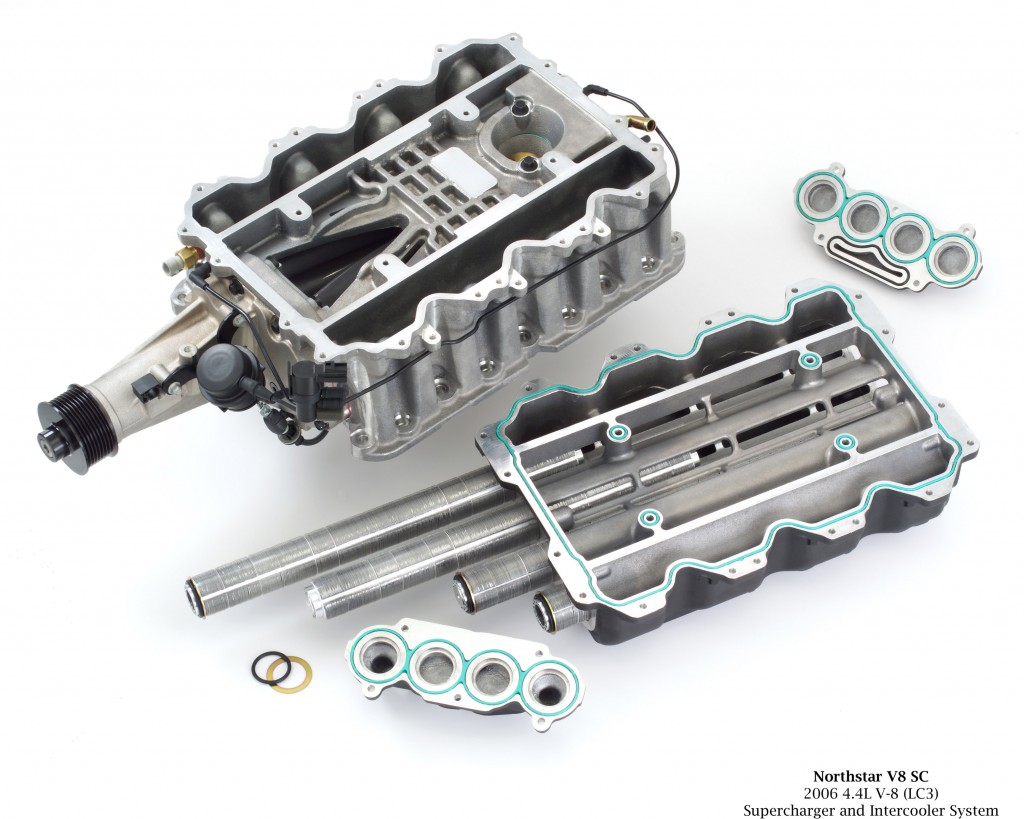

In the Cadillac STS-V, air flows through the rear-mounted throttle body, into the supercharger, up through the intercooler, and down into the manifold. The IAT2 intake air temperature sensor after the intercooler is in the base of the supercharger section shown in the photo above in the top left corner in the air flow to the manifold.

Water injection or methanol injection development

Water injection was originally developed and tested by Sir Harry Ricardo (1885-1974). Among other projects, such as development of the octane rating, Sir Ricardo did testing and development of water injection. His work was the basis for the German fuel MW 50, a 50/50 mix of methanol (an alcohol) and water used in the WWII German fighter Focke-Wulf FW 190, and other Fighter aircraft. The methanol injection enabled the FW 190 to go from 1600 hp to 2000 hp. The P-51 also later used methanol injection.

Post-war methanol injection was sometimes installed as an automatic power reserve system (APR) for use in hot or high altitude takeoff.

Water / methanol injection in automobiles

The 1962 Oldsmobile F85 and Corvair Spyder offered water injection, as did the Saab 99 Turbo S later, after 1978. In automobiles as in aircraft the purpose of water or a mix of water and metanol is to cut the temperature of the incoming air in supercharged or turbocharged engines.

The science behind water injection or methanol injection

The latent heat of gasoline is 140 btu/lb. The latent heat for water is 700 btu/lb. This means that water will remove five times more heat when vaporizing than gasoline does. When water injects into the air stream, the fine droplets of water allow the most water surface area for rapid vaporization. Expansion of the water into steam also assists with cylinder pressure. A side benefit of water injection is removal of deposits in the intake track.

Some will argue that lowering the air temperature or cylinder temperature in and of itself will not add power. Although lower temperature, denser air is available, without tuning to allow increased timing to take advantage of the lower temperature air there will be little gain. This argument overlooks the effective self-tuning of modern engines by removal of high incoming air temperature retard adders. More to the point however, tuning for a water injection or methanol injection at the time of installation is best.

Water or water and methanol mix or 100% methanol?

Water injection alone provides air temperature and cylinder temperature reduction. Injecting a mix of water and methanol provides a mix of cooling and additional high octane fuel. Use of 100% methanol increases the fueling at the expense of some loss of cooling.

100% water is not combustible. Up to a mix near 50/50, a water and methanol mix has limited combustibility. 100% methanol is highly combustible. For refilling, water is most available, and a mix of water and methanol is commonly available in the form of low temperature windshield wiper fluid. Pure methanol is a speed shop or specially sourced item.

A mix of water and methanol provides a good compromise between cooling, fueling, and safety.

Components of a water injection or methanol injection system

A water injection or methanol injection system is relatively simple. A reservoir or tank holds the fluid, which is pumped at a high pressure to a nozzle. The nozzle atomizes the fluid, spraying a measured amount into the intake. The amount of spray depends on the type of nozzle and system pressure. The system may use boost pressure or other engine indicators to trigger spray.

Methanol injection installed — Steve posted this report on his 2012 Cadillac CTS-V to youtube:

Methanol in wind shield wiper fluid

A partial list of some window wiper fluids and their content. Look for % methanol in the range desired, water for the rest, and minimal ‘other stuff’.

| Product | Methanol | Water | Other Stuff |

| Peak | 35 | 59 | 6 |

| Turbo Power -40C | 40-50 | 50-55 | <1 |

| -20F Super Tech | 30 | 70 | 0 |

| Rain-X all-season | 20-35 | 50-90 | 1 |

HEET gas line anti-freeze appears to be 99% methanol and 1% proprietary other stuff. Some sites suggest adding a container of HEET to a windshield wiper fluid base to reach a desired methanol %.

Water injection or methanol injection safety:

Please note the material data safety sheet when discussing methanol warns:

DANGEROUS FIRE AND EXPLSOION HAZARD WHEN EXPOSED TO HEAT OR FLAME. METHANOL IS EXTREMELY FLAMMABLE AND FORMS EXPLOSIVE MIXTURES WITH AIR. METHANOL VAPORS MAY TRAVEL CONSIDERABLE DISTANCE TO A SOURCE OF IGNITION AND FLASH BACK

Methanol burns invisibly, is toxic if you get it on your skin, corrosive if you get it in your eyes. When considering any activity involving even small percentages of methanol please take appropriate precautions.