I plan to update this page with notes on variable valve timing tuning for the LC3 DOHC VVT Supercharged V8 in the STS-V.

Cam Phasers: [ref]

Intake: Initial timing 133 degrees ATDC with 40 degrees advance authority

Exhaust: Initial timing 117 degrees BTDC with 50 degrees retard authority

Valve Lift: Intake: 10.5mm (.413 inch)

Exhaust: 10.0mm (.394 inch)

Duration @ .050″

Intake: 202 degrees

Exhaust: 214 degrees

VALVETRAIN VARIATIONS

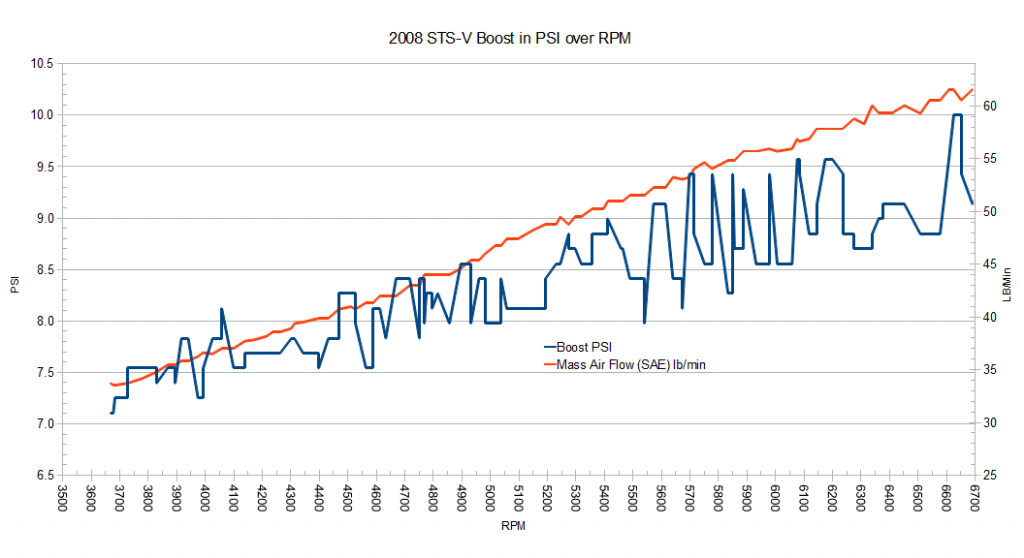

One of the key elements in achieving the broad output of the LC3 is the variable valve timing (VVT) system. With VVT, the seemingly opposed objectives of smooth and torquey low-end output, and massive specific output to a peak at 6400 rpm become possible, using individual hydraulically actuated phasers on each of the four camshaft. “Four-cam VVT is an exceptional performance enabler, but also provides the control flexibility needed for highly advanced NVH and emissions characteristics,” said Dave Caldwell, Northstar V-8 SC development and calibration engineer. “The supercharger module and VVT system complement one another, resulting in a genuine luxury and performance engine.”

This system allows the camshaft phasing to be altered in relation to the piston position, as well as in terms of event timing between the intake and exhaust camshafts. The VVT system was introduced last year on the normally aspirated Northstar 4.6 liter V-8, and the system received all-new command strategy optimized for the supercharged 4.4 liter application. The variable valve timing system makes it possible to target optimal idle quality, control cylinder pressure and detonation, and enhance drive-ability, while providing for the high-speed breathing necessary to turn a number at the top of the power band. Another advantage of the system is a reduction in exhaust emissions, which effectively eliminated the need for supplemental emissions equipment in the form of air injection or exhaust-gas recirculation systems while meeting today’s stringent emissions standards.

- Advance intake and exhaust => more low-RPM power, less high-RPM power

- Retard intake and exhaust => more high-RPM power, less low-RPM power

- Less overlap => lower EGTs, faster turbo spool, less fuel

- More overlap => higher EGTs, slower turbo spool, more fuel

- Conclusion: Advance Both at Low RPM, Retard both at High RPM

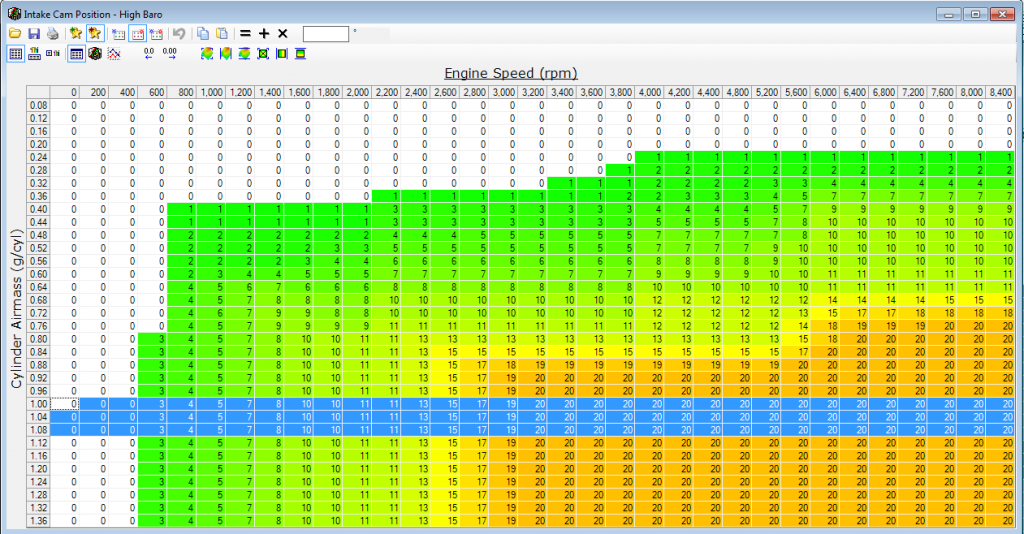

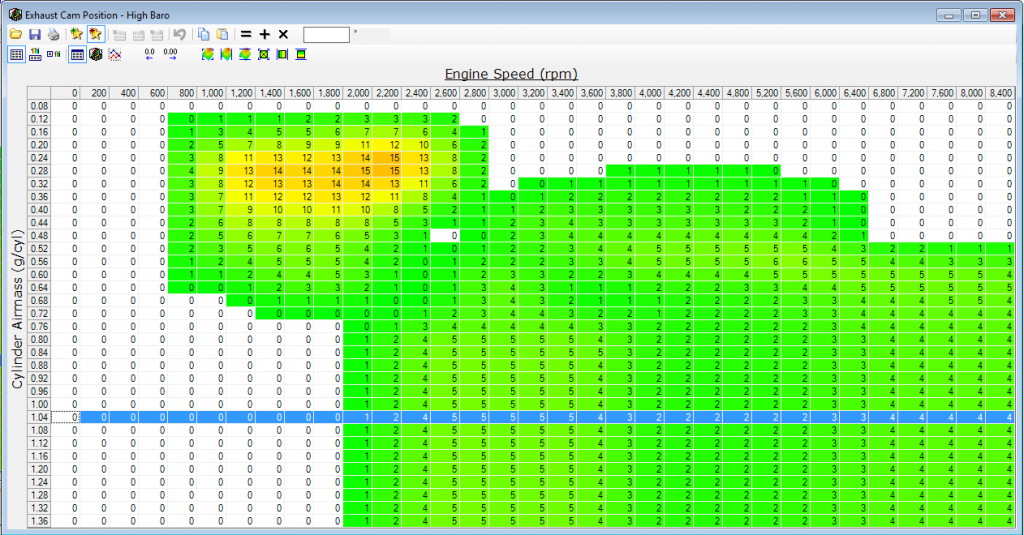

What is happening in the VVT cam programming for the LC3:

Intake: From 3200 to 6400 RPM, position set at 20 degrees

Exhaust: At low RPM position set at 5 degrees, decreasing to 2 degrees at mid and back to 5 degrees at high RPM