Update: IAT2 test results added

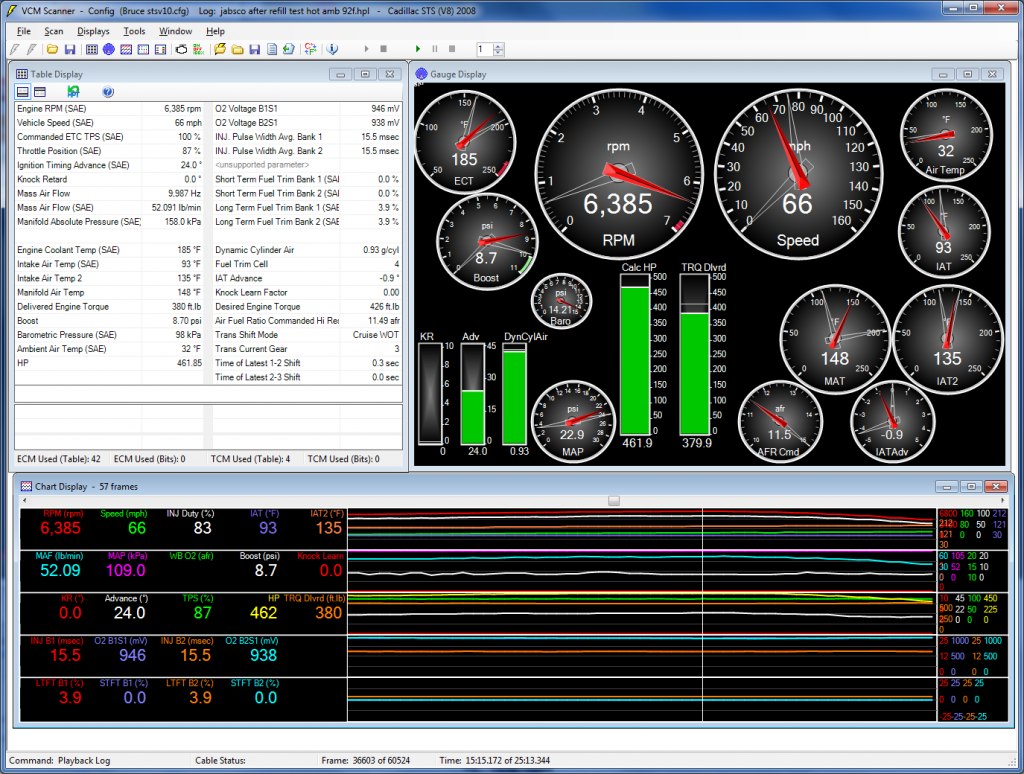

Today I performed an intercooler pump test on the Jabsco 50840 12v pump as a replacement for the Bosch OEM intercooler pump in my Cadillac STS-V. The Cadillac STS-V uses the Bosch 00 392 022 006 pump.

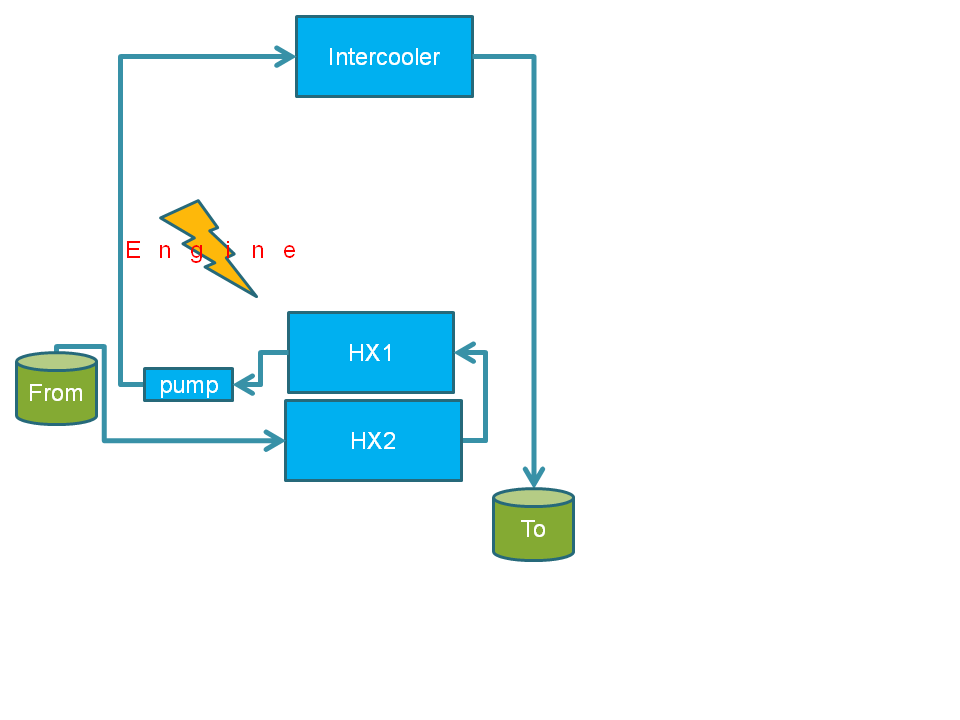

My Cadillac has a 2nd heat exchanger, an S3 provided by Timmy C, and uses a 1 gallon AVS inline intercooler tank. The goal of these tests is to improve intercooler cooling, which will enable the supercharged V8 to make more power.

Intercooler pump test setup

To run a bucket test I put a FROM bucket at intercooler height, flowing into the pump and system, and out from the intercooler to a TO bucket. This is similar to my previous intercooler pump test setup, for continuity. I have added a TO bucket that is a mixing bucket which makes it very easy to measure output.

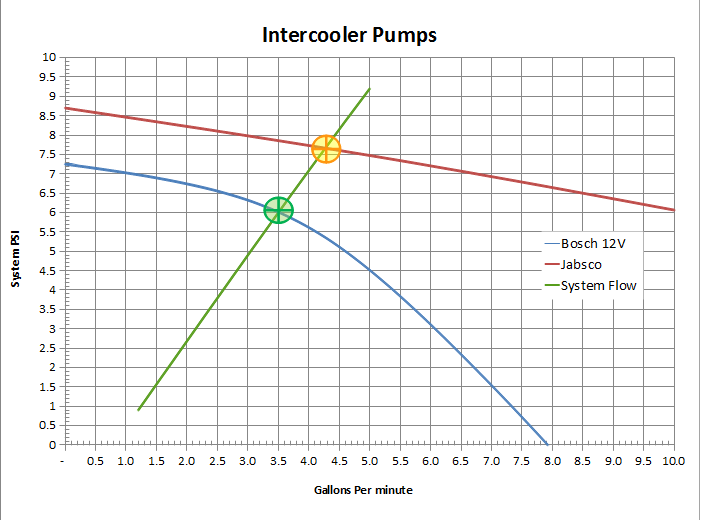

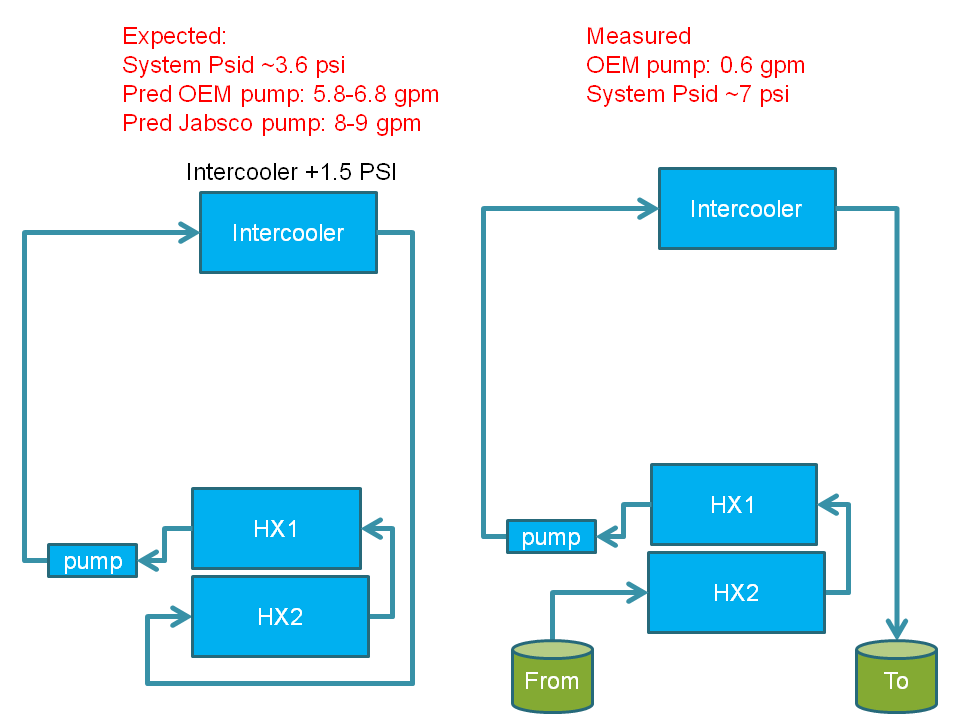

Predicted intercooler pump test flow:

The Jabsco centrifugal pump does 29 gpm against no resistance, and the Bosch pump does 8 gpm against no resistance. In an actual system the pump curves overlaid with the system resistance curve predict where the pump will actually run in that system.

Intercooler Pump Test Results

In today’s test the Jabsco pump measured at a steady 2.25 gallons per 30 seconds, or 4.5 gpm (gallons per minute). Previously, the Bosch OEM pump ran at 3.5 gpm, which would suggest the system pressure at that flow was 6 psid. As flow increases, the resistance pressure in the system increases roughly at the square of the flow. I expected the Jabsco pump to run 4.3 gpm, so the 4.5 gpm is good. The Jabsco has 1/3.5 = 28.5% more flow than the OEM pump.

I still have more work to do to complete pump installation. I will retest with the pump in place. I will follow-up the intercooler pump test with IAT2 tests to see how the new higher flow impacts intercooler cooling.

Intercooler Pump Test Update

Today I completed the pump install and conducted a test run with the new pump:

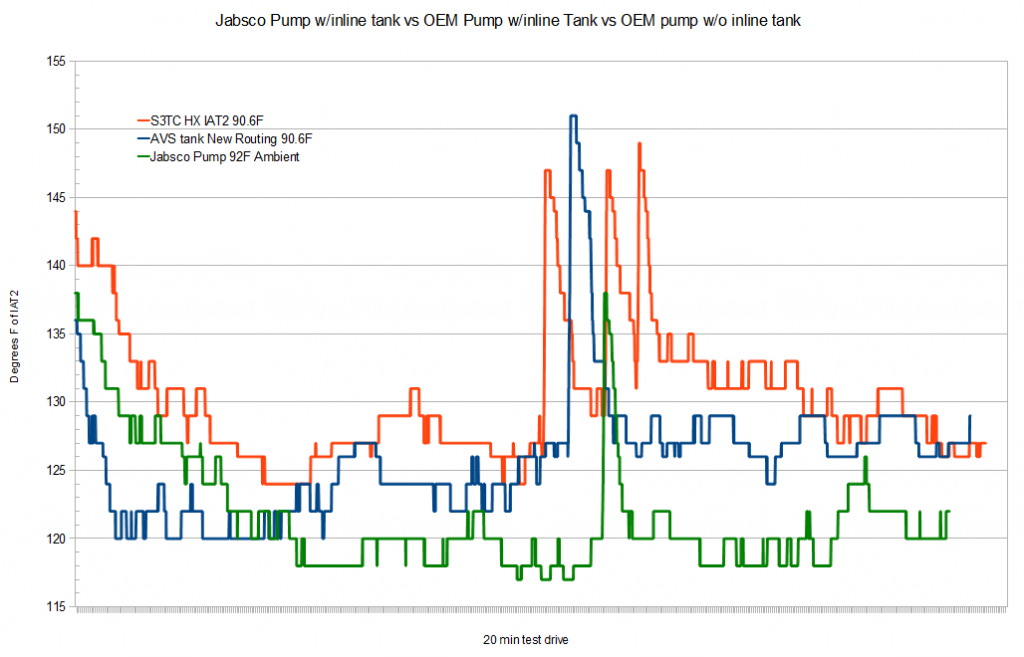

Click on the graph for a larger version.

What this graph shows is temperature in degrees F on the Y axis, over a 20 min drive on the X axis. Spikes in the graph represent acceleration runs. The red line is the OEM pump without the inline tank; the blue line is the OEM pump with the inline tank; the green line is the Jabsco pump with the inline tank. Today it is 92F ambient; on the prior test days it was 90F ambient air temperature.

I read this test result to show that the jabsco pump’s greater flow allows the system to reach an IAT2 equilibrium temperature of 118-120F, an improvement of 7F. The acceleration spike is a 20F increase, an improvement of 5F in addition to the lower equilibrium, so that at peak temps are 12f lower than previous hot day.

Intercooler pump test conclusion:

The Jabsco pump has a 1 gpm higher flow than the OEM Bosch pump. This 1 gpm greater flow lowers the operating IAT2 temps by 7F