Today I took the STS-V front clip off again for some adjustments and a new tank install.

My first goal was to work on improving the lower OEM Heat Exchanger (HX1) hose routing that appeared to be crimping. Second was to transform the flow from intercooler HX2 HX1 pump to intercooler HX1 HX2 pump due to elevation differences. I also wanted to change the S3TC HX2 fittings from plastic to brass, and redo them in general to ensure no leaks. Finally, if it fit (and it does) I wanted to try adding in my AVS 1 gallon aluminum inline tank.

Here is a shot

The tank seems upside down, but this placement allows the ‘drain’ to act as an air release if needed, and the tank brackets are tied off above so that the tank is ‘hanging’ in place, along with the hoses pretty much keeping it where they want it to be.

The flow now is intercooler to OEM HX to inline tank to S3TC HX to pump to intercooler. That matches the way GM did the flow for the inline tank they use with the LS9.

The tank is clearly visible in all its steampunk glory through the front mesh grill. I suppose painting it black would fade out the tank, but I am more interested in testing how it performs just now. The inline tank wants to be in the incoming air flow also to help with temperature control.

The OEM STS-V intercooler cooling system holds 2.6 quarts. HX2, the S3TC HX, holds 2 quarts. The new tank holds 1 gallon (4 quarts). So the system now has 8.6 quarts instead of 2.6 OEM quarts.

Update:

First test the intercooler temps etc and see if everything is playing well together.

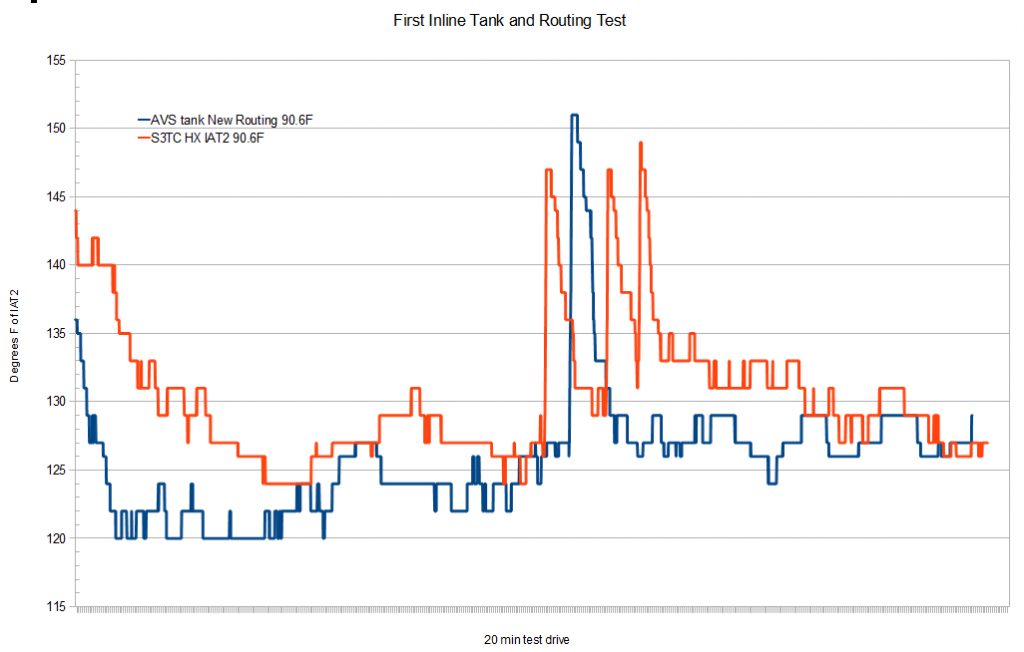

The blue line is today’s IAT2, or intake air temperature after the supercharger and intercooler during a set route test drive. The red line is a previous day with the current config except no inline tank, and the HX1-HX2 flow path was different. The spikes are acceleration runs. Both days were 91.5F ambient temps, so seem comparable.

What this appears to show is that the IAT2s are lower with the new inline tank, but actually ran higher during the acceleration run. I need to zoom in on that in a different graph (below).

Overall good news for the new inline tank.

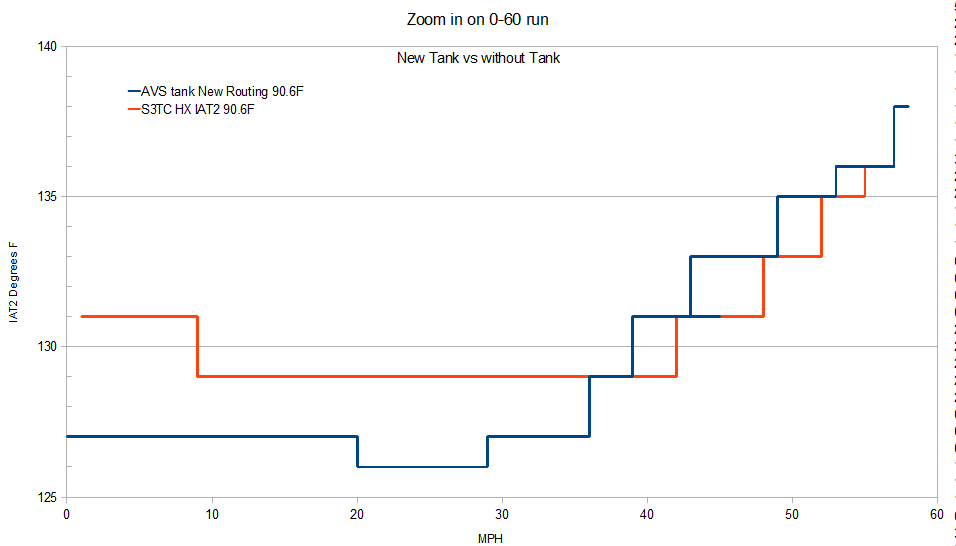

Conventional wisdom is that more fluid in the system provides a time buffer to IAT2. What we see in this graph is that the new tank did no better at delaying IAT2 increase during 0-60 than the system without a tank. In both systems due to the system flow rate during the 0-60 run the system never gets through all the coolant. My measured 3.5 gpm means that even with 1 gal of fluid in the system, that gallon is circulating every 17 seconds. With 2 gallons it is circulating (if the 3.5 gpm is still constant) every 34 seconds. So unless we speed up the pump (stay tuned) or measure over a longer acceleration run, one might expect to see no difference.

However, the fact that the system reached a lower temp with the new tank and configuration is a good result.

The following video shows HP Tuners gauges during the acceleration run with the new inline tank:

Does the tank have any effect on the engine/trans cooling at all? Wondering if it blocks airflow which it would seem to do – how say you?

I prefer to say that it is USING that airflow 🙂

I have been watching my engine temps to see if any issues, but with local temps 90F+ the engine coolant temp is fine. It does look a bit odd through the grill, but I am advised by son2 that only a car enthusiast would notice.

Pingback: Cadillac STS-V Intercooler Flow GPM Bucket Test 3 | Cadillac Conversations

Bruce,

There is something wrong with your intake setup. At WOT your IAT’s should be much closer to ambient. At highway cruising speed and at WOT I am 1-3* above ambient and temps here are 100+. Did you re-route the coolant hose that stock went above the intake?

Also, I think you will pleased with the new pump results when you get it in.

PGA2B, It is possible that there is still an issue with thermal isolation of the intake, although when the install was being done we checked each of the images in real time step by step. Keep in mind that a lot of my studies are with the engine heat soaked. I have also considered adding a thermal barrier below the run of the intake to ensure it is as isolated as possible, so I will reexamine the run and see what could be improved.

No problem. As I said on ctsvowners, in stop and go forget it! I can see IAT’s 140-160. Funny thing is that my IAT can surpass my IAT2 at times! It is highway and WOT that my temps are well in check. I will be changing pulleys pretty soon also. I am going to test a 2.6, 2.5, and 2.4 to see which one is best with no belt slip.

Darn 0-60 runs start from 0 so that induces some rise. But we have always wondered if my intake is quite right.

Very interested in your pulley tests. I think they depend on iat2 control, so I would like to see someone document exact effects on air temps.